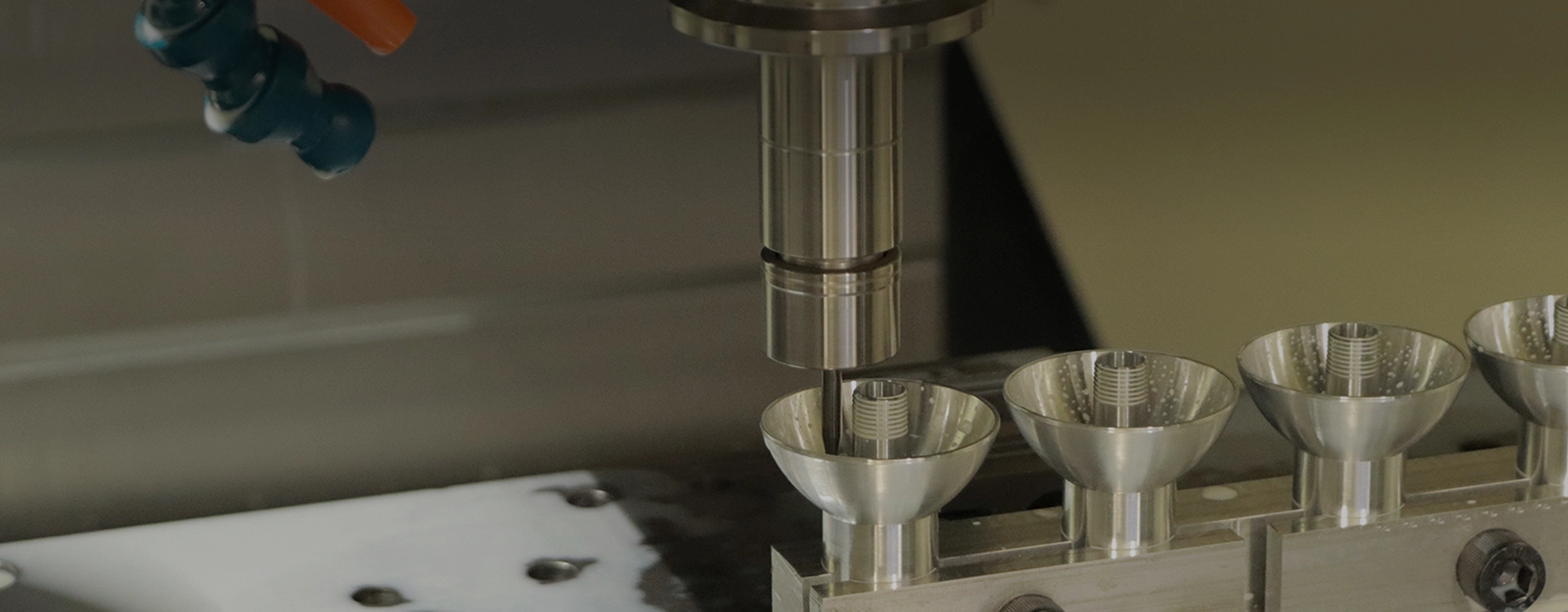

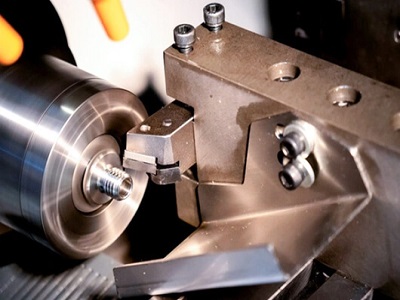

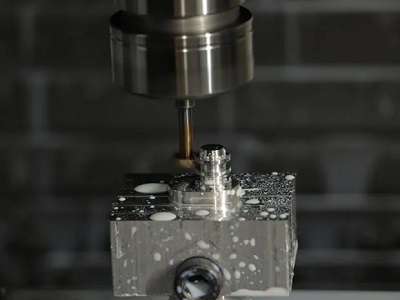

MQJM specializes in custom CNC milling service, bringing over 12 years of focused CNC machining experience and an average of 15 years of experience within our engineering team.

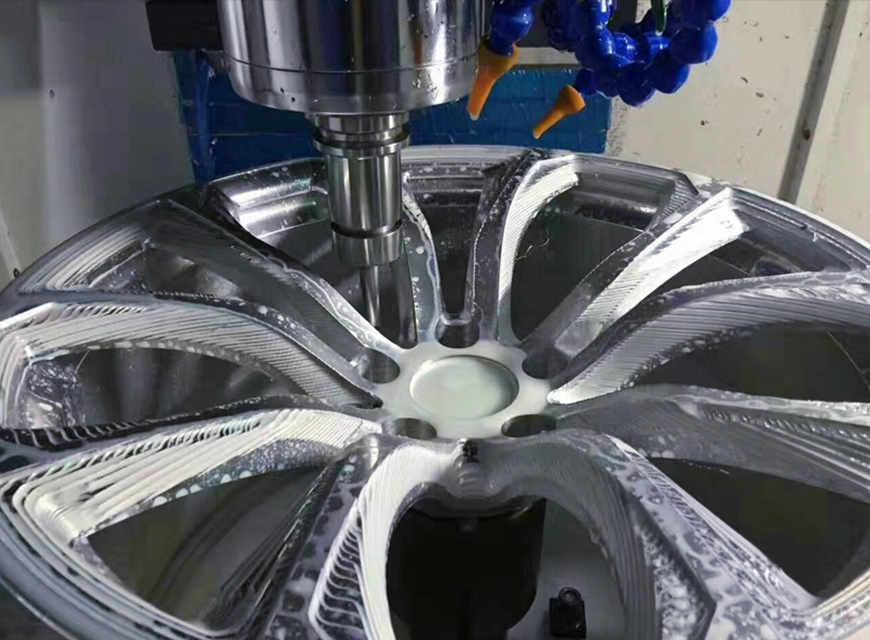

CNC milling is extensively used in the automotive industry to manufacture high-precision parts such as engine components, gearboxes, and custom fittings. It allows for the creation of complex shapes and designs, contributing to the efficiency and performance of vehicles.