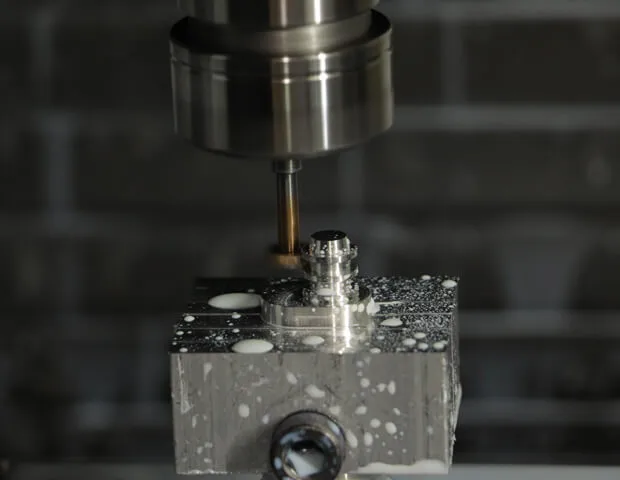

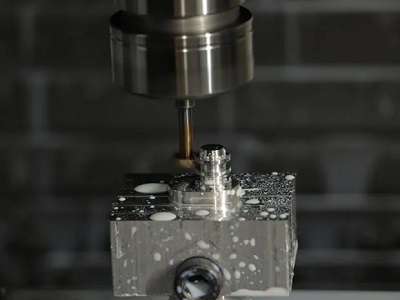

CNC Milling Stainless Steel Parts

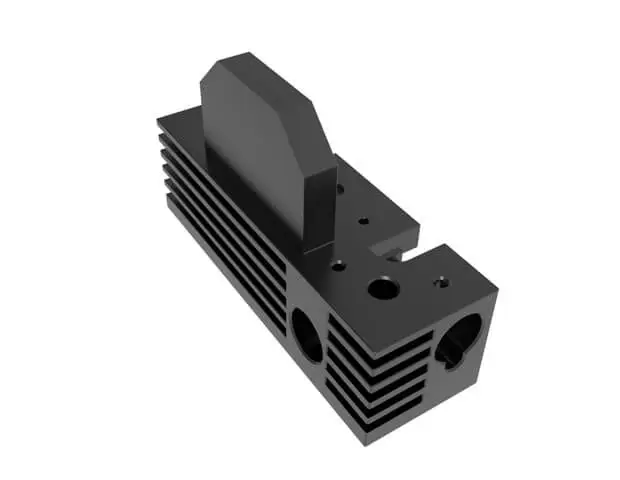

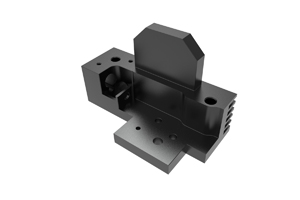

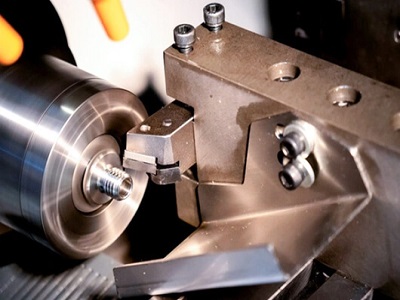

MQJM is a premier metal machining company providing high-quality services of CNC milling stainless steel parts. We use advanced 3, 4 and 5-axis CNC machining technology to create custom cnc machining stainless steel parts with excellent mechanical properties, high precision and repeatability. We are able to produce high-quality custom CNC milling stainless steel parts for complex projects, maintaining extremely high precision and tolerances, fully complying with required technical specifications, while achieving time and cost savings.

Specializing in custom CNC machining stainless steel service for decades, MQJM has become one of the most reliable and affordable suppliers in the industry. We use advanced multi-axis stainless steel CNC machines for part processing to ensure optimal quality and accuracy. Our technical team has an in-depth understanding of every detail of custom CNC machining stainless steel and excels in manufacturing processes such as CNC steel milling, turning, drilling and steel prototyping.