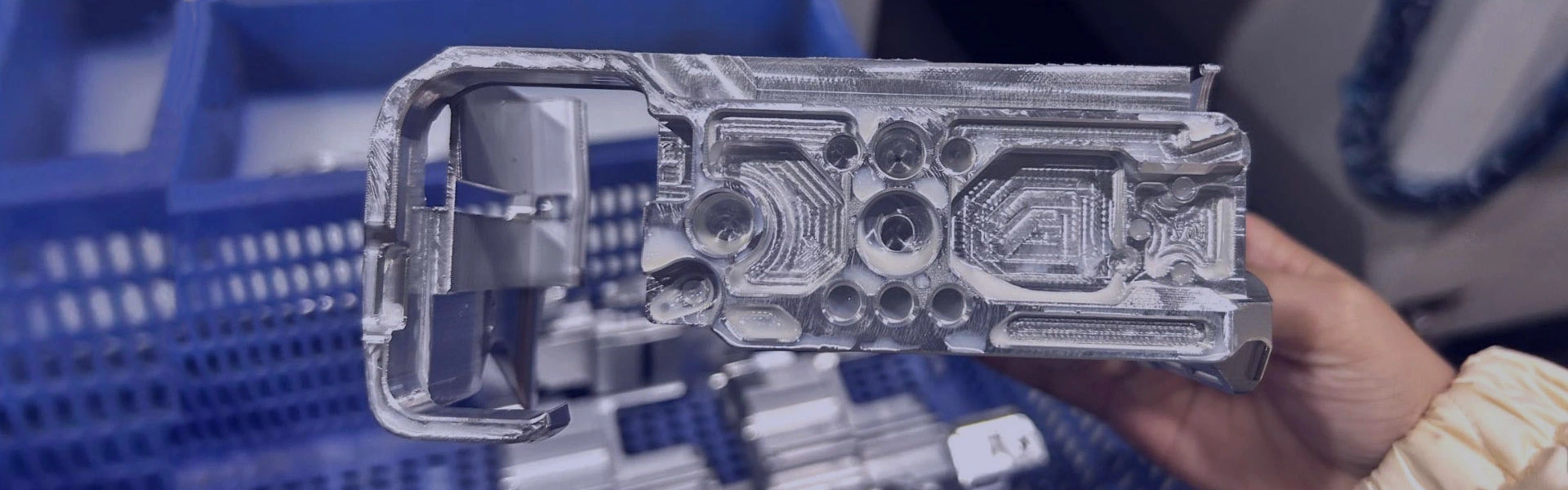

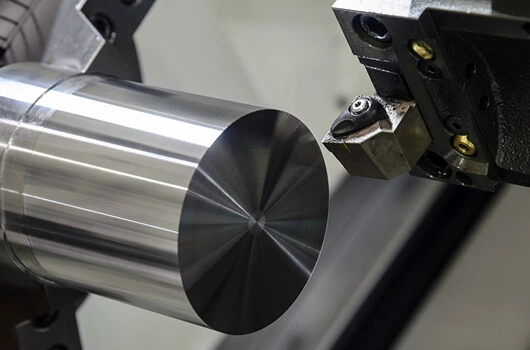

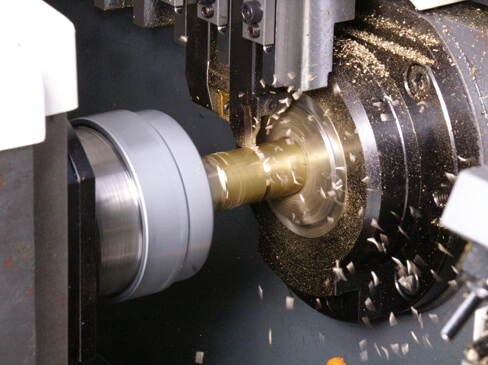

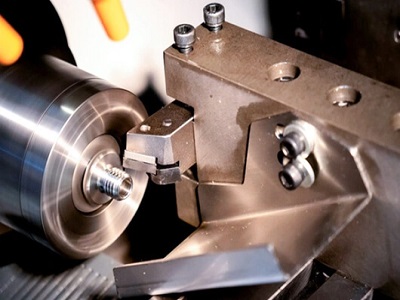

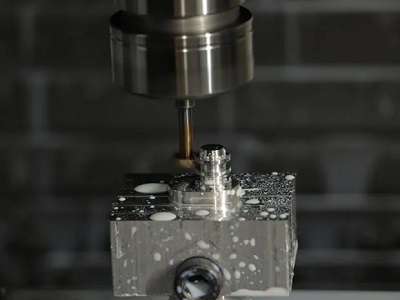

Based on 12 years of China CNC milling service experience, we focus on the manufacturing of racing parts. With more than 40 3-, 4- and 5-axis CNC machining machines, we achieve efficient production. We have supplied specialist parts to numerous global racing cars and are well versed in industry standards. Industrialized and professionally oriented, our team expertly operates all types of machines ensuring that every part meets stringent specifications. When you choose our CNC milling services, you choose an experienced and efficient partner to provide reliable and precise parts manufacturing for your racing project. Learn more...