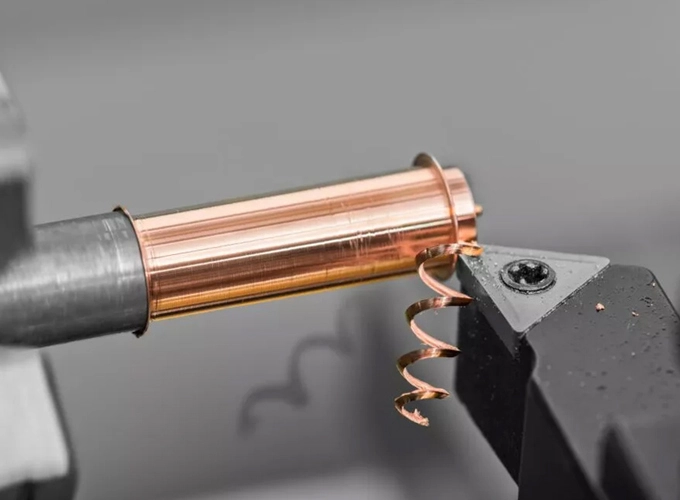

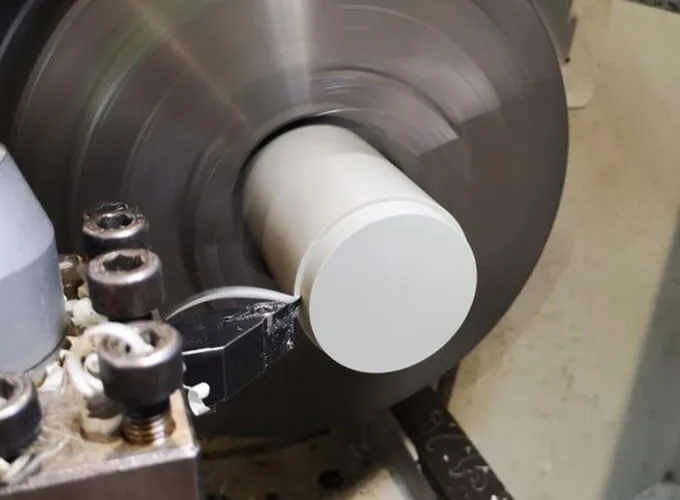

Our CNC turning services cover a wide range of materials, including metals (such as aluminum, steel, stainless steel) and plastics (such as ABS, POM, Acrylic), as well as over 40 other common materials.

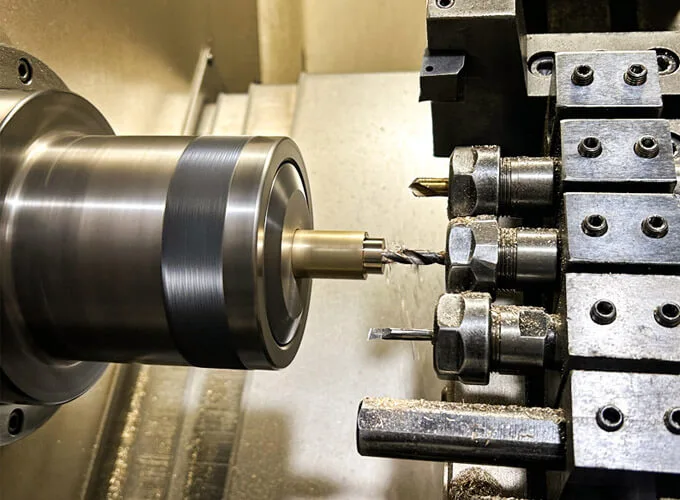

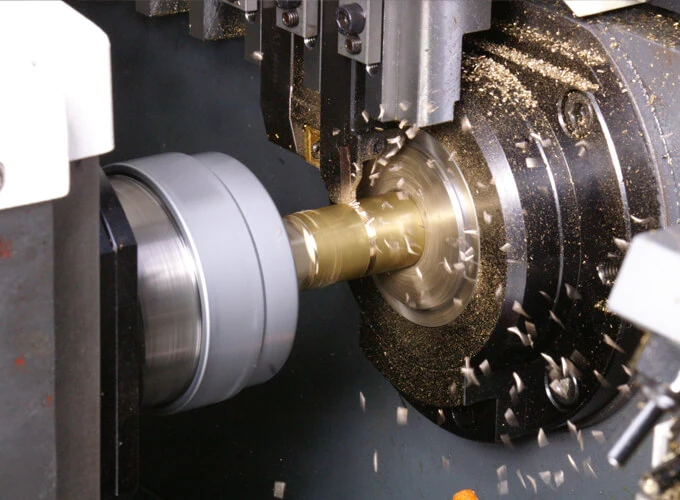

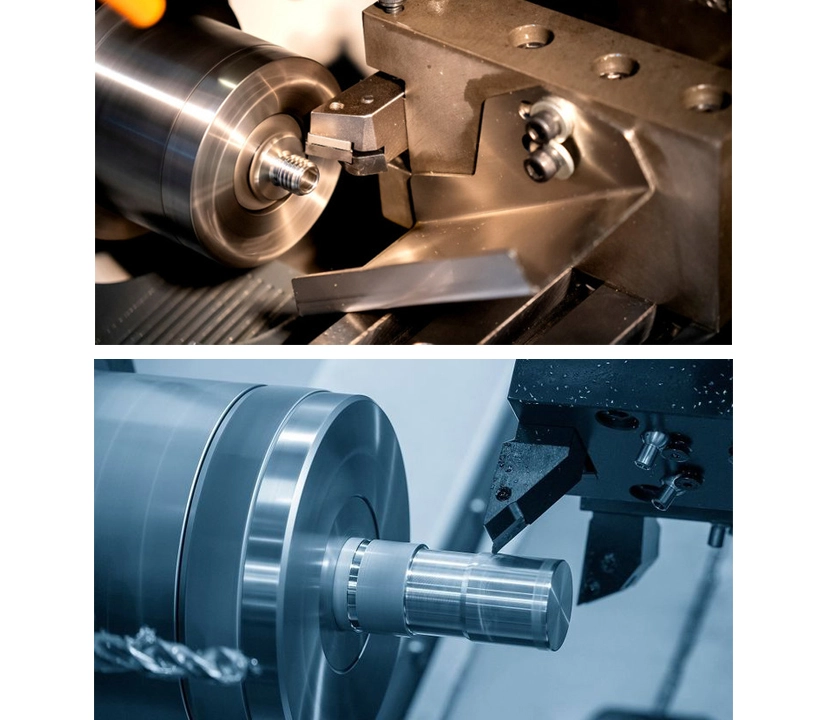

In MQJM's CNC turning service, the workpiece is securely clamped onto a rotating spindle, while a cutting tool systematically removes excess material either axially or radially, ultimately shaping the workpiece to meet specific dimensions. CNC Turning can be broadly classified into rough turning and finish turning. In rough turning, the cutting tool moves with a larger feed rate and depth, swiftly eliminating a significant amount of material to create ample allowance for subsequent processing. Conversely, finish turning employs smaller feed rates and depths to enhance surface smoothness and precision, ensuring the workpiece attains the required final dimensions and surface quality. The CNC turning technique is widely applicable across various materials, including metals, plastics, and composite materials. With the continuous evolution of Computer Numerical Control (CNC) technology, CNC turning service from MQJM has become predominant, leveraging a computerized control system to automate tool movements and achieve heightened precision and production efficiency.

CNC turning services from MQJM is a mechanical machining process controlled by a computer numerical control (CNC) system, used for processing rotationally symmetric workpieces. The following is the fundamental working principle of CNC turning:

1: Numerical Control Programming and Setup

Develop machining plans and convert designs into numerical control programming, while establishing zero coordinates for both the tool and the CNC turning parts.

2: Workpiece Clamping and Tool Selection

Secure the workpiece on the rotating spindle and choose appropriate tools to meet machining requirements.

3:Numerical Control System Operation and Real-time Monitoring

The numerical control system guides tool movements via computer control and simultaneously monitors cutting parameters to ensure a stable CNC turning process.

4: Automated Cutting Operations

Utilize the precision control of the numerical control system to achieve high-precision, efficient machining of the CNC turning parts, maintaining flexibility to adapt to various design requirements.

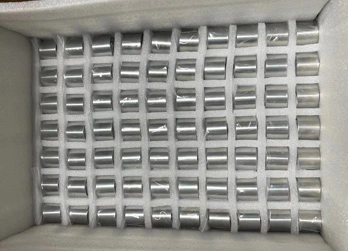

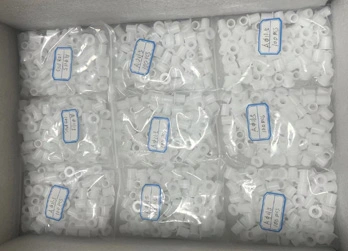

MQJM employs customized packaging solutions tailored to different types of CNC turning parts, ensuring that customers receive goods that meet satisfaction in terms of appearance, safety, and overall quality. We meticulously design each packaging method to accommodate the specific nature of the CNC turning parts, guaranteeing they remain undamaged during transportation. This detail-oriented packaging strategy not only reflects MQJM's dedication to product quality but also aims to provide an exceptional CNC turning service, ensuring customer satisfaction upon receiving the CNC turning parts.

MQJM is a leading manufacturer of CNC turning components in China, standing out with top-notch prototype manufacturing services and extensive mass production capabilities with over 30 various lathes.

We specialize in providing adaptable, swift, and stable CNC turning services to produce high-precision, high-quality components. Upon uploading CAD or 3D files, our professional team will offer free review, drawing optimization, quotation, and Design for Manufacturability (DFM) within 12 hours, providing comprehensive support for your project.

As a one-stop CNC turning service provider, MQJM excels in meeting the needs of rapid prototyping and small to large volume production. We are committed to delivering flexible, high-quality CNC turning components to ensure timely delivery and budget compliance. Choosing MQJM means choosing a professional, efficient, and reliable CNC turning components supplier, allowing our team to navigate and support your project seamlessly.

The following table summarizes recommended values and basic design considerations aimed at improving aesthetics, enhancing manufacturability, and reducing overall production time.

| Part size limitations | Metric units | Imperial units |

| Maximum part diameter | 508 mm | 20 inch |

| Maximum part length | 1066.8 mm | 42 inch |

| Maximum swing over the carriage | 355.6 mm | 14 inch |

| Maximum spindle through-hole | 50.8 mm | 2 inch |

Maximum speed: 5000 RPM

Motor power:750w

Our CNC turning services cover a wide range of materials, including metals (such as aluminum, steel, stainless steel) and plastics (such as ABS, POM, Acrylic), as well as over 40 other common materials.