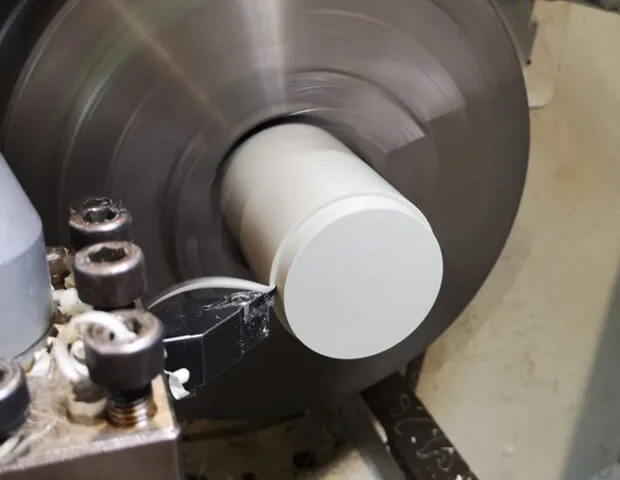

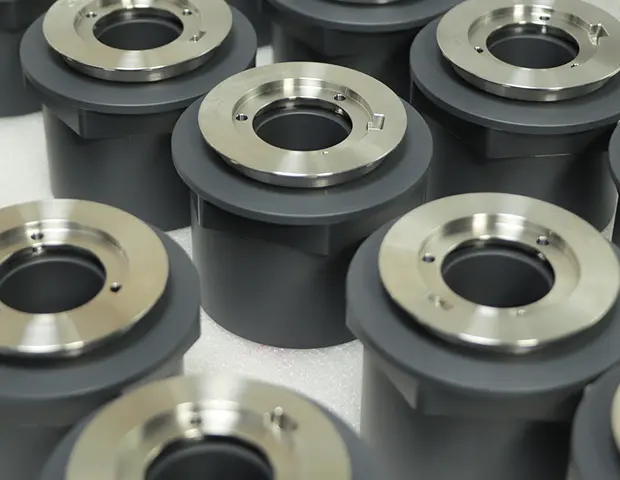

Plastic Turning Parts

Are you looking for a reliable, quick-turn supplier of plastic cnc turning parts?

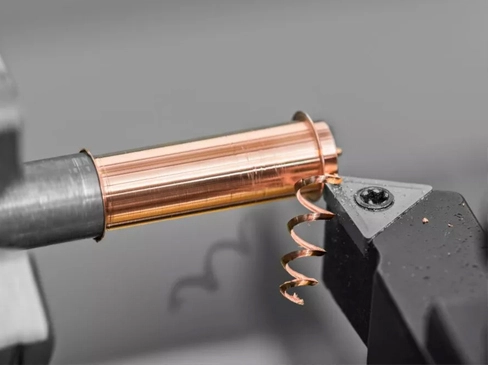

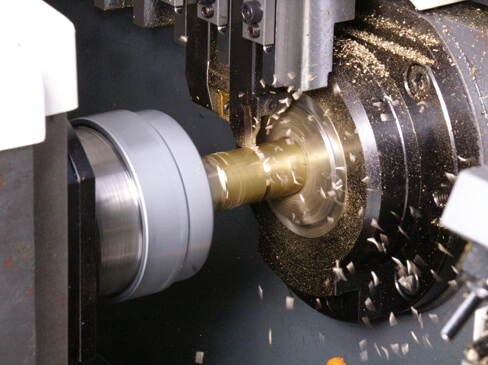

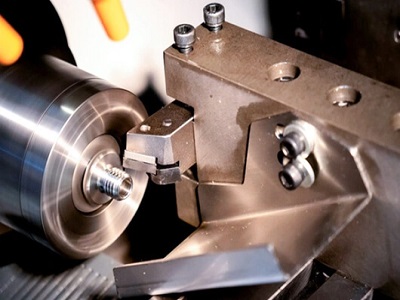

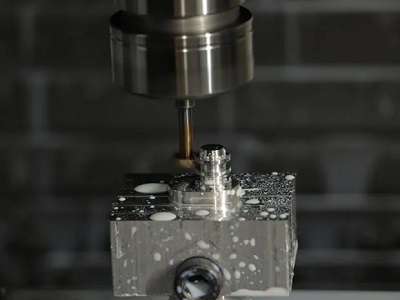

Through CAD model design and preparation, plastic turning materials such as ABS, POM, PEEK, etc. are selected and design specifications and dimensions are clearly defined. Securely clamp the workpiece on the CNC machine, select and set cutting tools, and perform CNC turning. Throughout the entire process, dimensions are checked regularly and adjustments are made, surface treatment is performed if necessary, and quality checks are performed at the end to ensure high-precision manufacturing.