Swiss CNC Machining

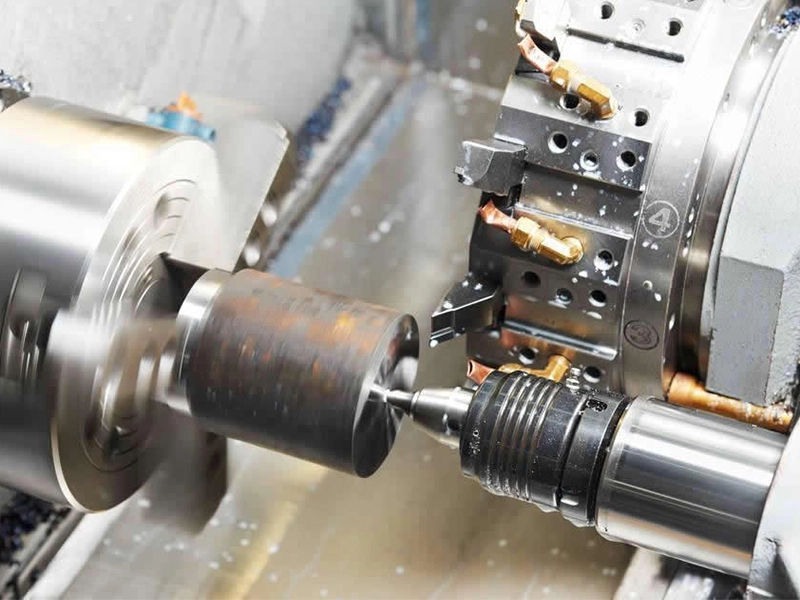

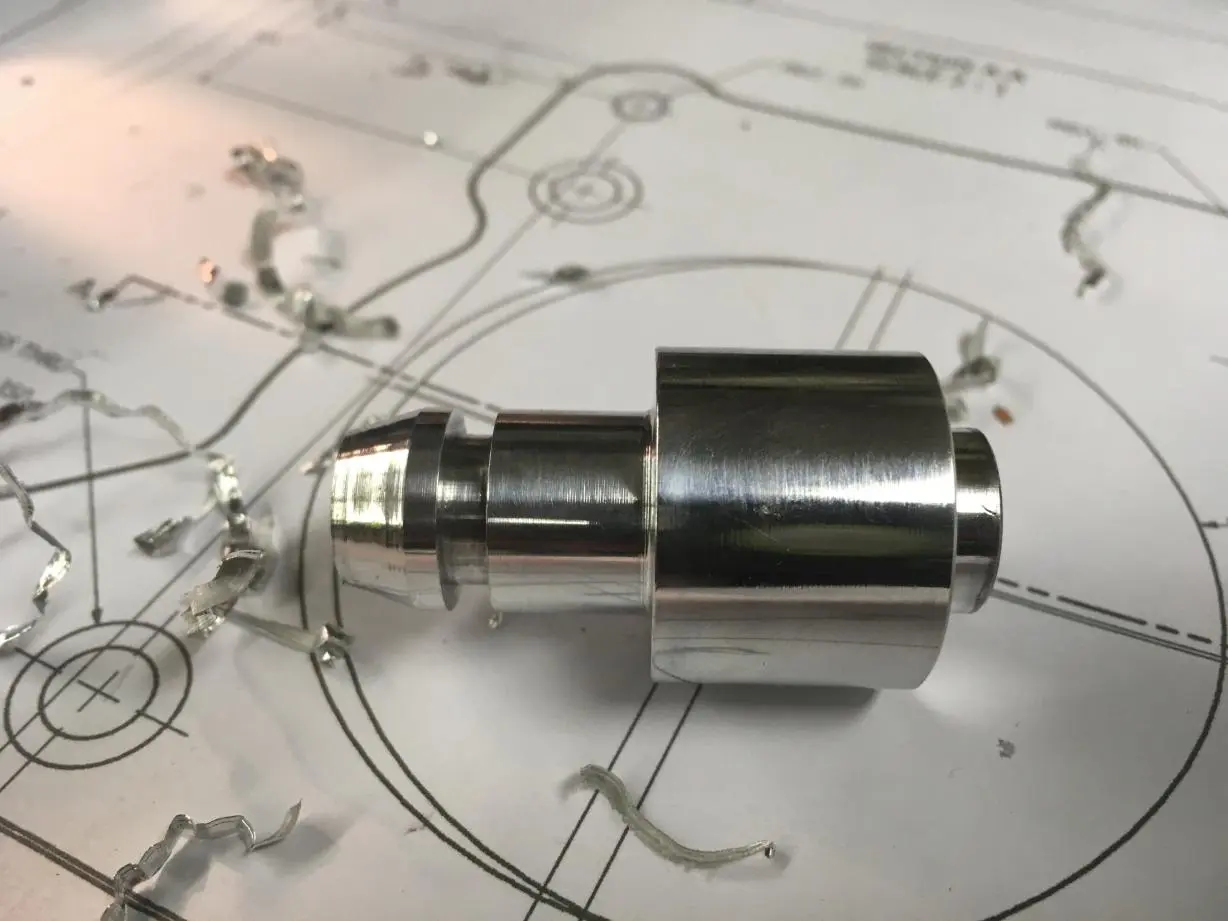

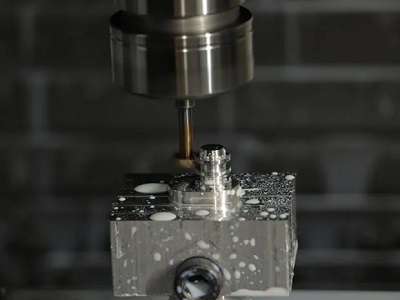

Swiss CNC machining is a specialized process designed for the manufacturing of small-sized, high-precision turned parts. Originally developed for the Swiss watchmaking industry, Swiss CNC machines, also known as Swiss automatic lathes, Swiss screw machines, or Swiss-type lathes, have evolved over the years and found widespread applications in various industries for large-scale, high-precision manufacturing— and with good reason.

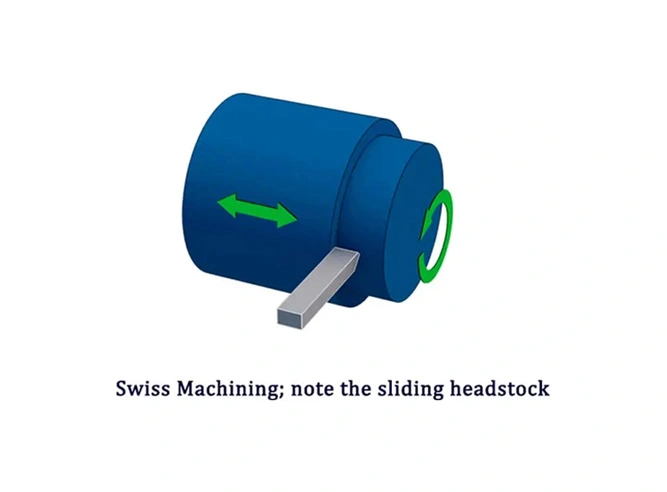

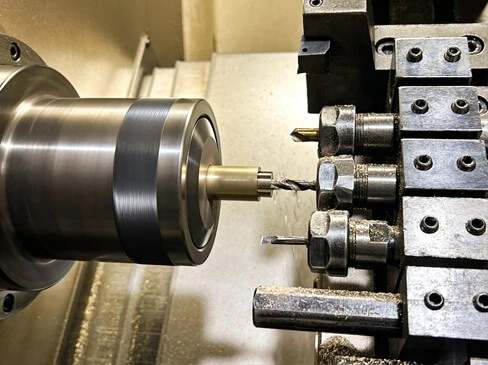

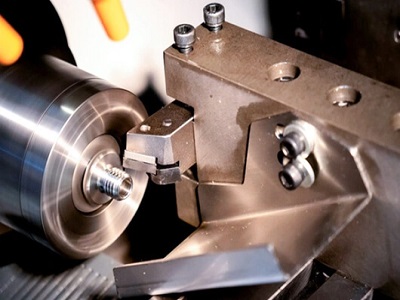

A Swiss CNC machine is designed to cut bar stock fed through a guide bushing while keeping the tool stationary. The collet recesses behind the guide bushing provide better support for the clamped bar stock, preventing direct exposure to the bed and fixtures. This enables the machine to process materials quickly and tightly. Furthermore, the cutting tool, working closer to the guide bushing, plays a crucial role in reducing tool deflection, vibration, and improving part accuracy.