In modern manufacturing, CNC milling stainless steel parts have become one of the core technologies in the field of precision machining. However, stainless steel materials face many challenges during the machining process. How to solve these machining difficulties and improve production efficiency and machining quality is a problem that many manufacturers are eager to solve.

Challenges in Stainless Steel Machining

Compared to traditional metal materials, stainless steel has unique material properties. Although its strength and hardness are not as good as some steels, it has high temperature strength and a large tendency for work hardening. This increases the cutting load during the machining process, leading to accelerated tool wear.

At the same time, stainless steel has a high cutting force. Especially with austenitic stainless steel, its elongation far exceeds that of ordinary steel materials, requiring greater force during cutting. Additionally, stainless steel chips are not easily evacuated during cutting, and chips tend to stick to the tools, increasing surface roughness and possibly causing tool surface flaking.

These machining challenges make the processing quality and production cycle of CNC milling stainless steel parts face significant challenges. Especially in industries with extremely high precision requirements, such as aerospace, power equipment manufacturing, and the food industry, the machining quality of stainless steel directly affects the performance and production efficiency of parts.

How to Overcome the Machining Challenges of Stainless Steel CNC Turning Parts?

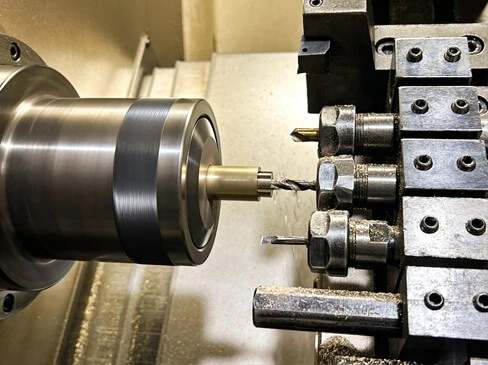

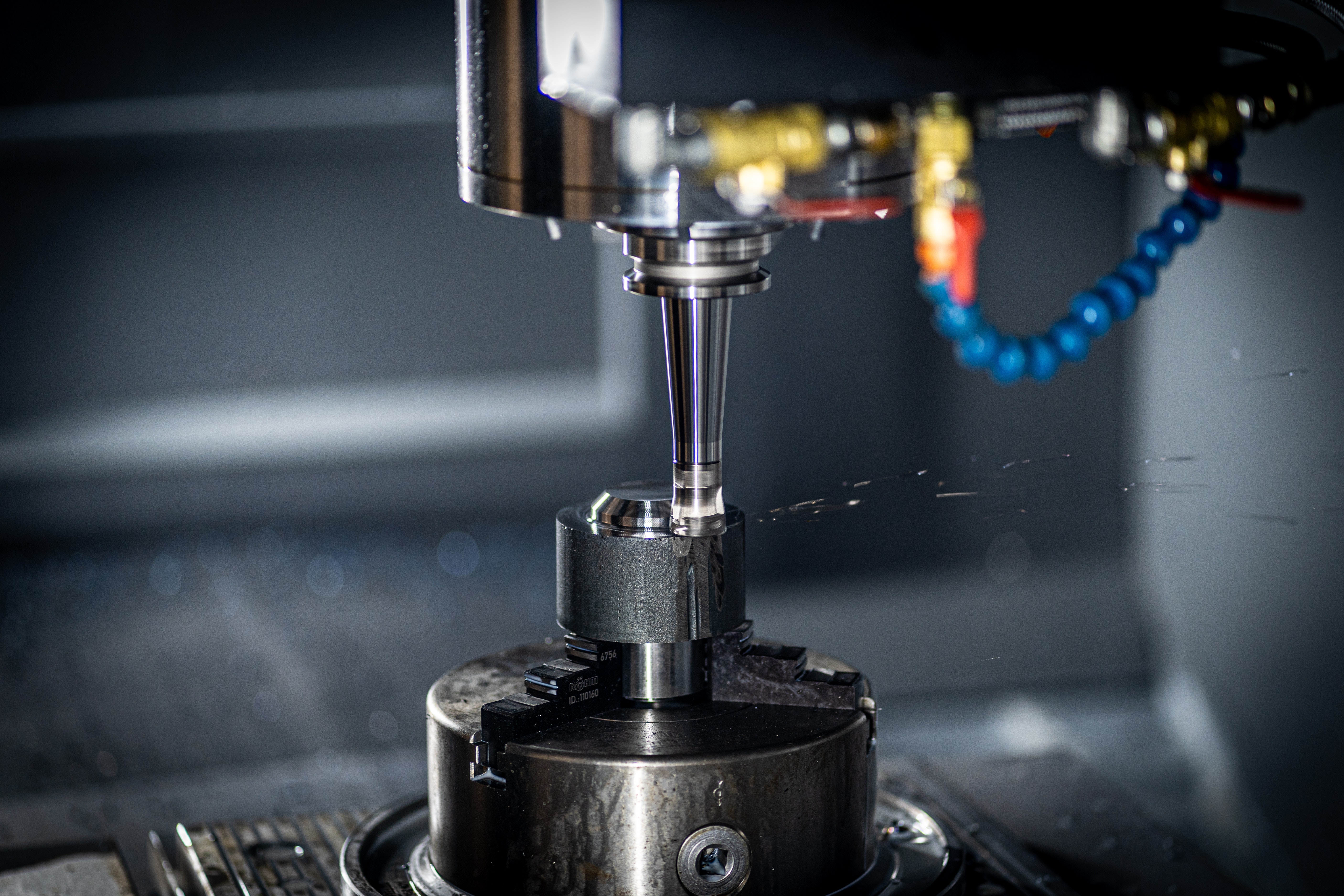

To solve stainless steel machining problems, it is first necessary to start by selecting suitable tools and optimizing cutting processes. CNC technology has obvious advantages in this regard. By precisely controlling cutting speed, feed rate, and tool path, CNC milling stainless steel parts can effectively mitigate work hardening and reduce tool wear.

Efficient Tool Materials and Coating Technologies: Using high hardness and high-temperature resistant tool materials suitable for stainless steel cutting, and applying special coatings to tool surfaces can significantly extend tool life, reduce wear and sticking during cutting.

Optimizing Cutting Parameters: Adjusting cutting speed, feed rate, and cutting depth, through a scientific combination of cutting parameters, can reduce cutting forces, decrease heat accumulation, and thus prevent tool overheating or workpiece thermal deformation.

Use of Coolants: For high-temperature stainless steel materials, reasonable selection and spraying of coolants can effectively reduce cutting temperatures and help chips to evacuate smoothly, ensuring surface flatness and accuracy.

Precision Control: Utilizing the intelligent control systems of CNC milling stainless steel parts to automatically adjust machining parameters, precisely controlling every aspect of the cutting process, ensuring dimensional accuracy and surface quality of parts during machining.

With 13 years of production experience, MQJM has become a well-known expert in CNC milling stainless steel parts in the industry. We are proficient in the machining of various stainless steel materials and can provide customized machining services for different industries, meeting demands from high strength and complex geometry to strict tolerances.

MQJM adheres to high standards of quality control in the production of CNC-processed stainless steel parts, from raw material selection to the optimization of machining processes to final quality inspection, ensuring that every part meets customer expectations and stringent industry requirements.